|

Shanghai ProMega Trading Co., Ltd.

|

Gold Index: 7003

Automatic Laminator Thermal Film Laminating Machine Big Size With PLC Control Plate

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Big Size Fully Automatic Laminator Thermal Film Lamination Equipment

Applications:

<

Big Size Fully Automatic Laminator Thermal Film Lamination Equipment

Applications:

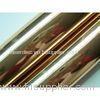

It is used for the lamination pre-glued film and paper.

Features:

Pro-TFL800 fully automatic laminator is designed for the lamination of pre-glued film and paper. This laminating machine is composed of feeding system, laminating system and cutting system. The electric and pneumatic devices are controlled by programmable control (PLC) system. Heating roll adopts oil circulation heating system to homogenize and stabilize laminating temperature. This machine centralizes the features of compact structure, high automation, humanized operation design, and is an excellent choice for large and medium-size enterprises.

Configuration:

1. Automatic paper feeder adopts oil-free vacuum pump to feed paper automatically.

2. Automatic paper feeding system is equipped with no paper protector and paper break protector, which are controlled by photoelectric and mechanical systems. When no paper or paper break occurs, the machine will stop automatically for self-protection.

3. Conveying table is furnished with air aspirator and front lay etc. to guarantee paper conveying and overlap stable and regular.

4. High precision of chrome plated heating roller is equipped with oil circulation heating system, which has excellent performance to temperature control. The laminating temperature is adjustable upon applications.

5. Pneumatic pressuring system provides automatically steady pressure to guarantee good laminating quality. The pressure is adjustable upon applications.

6. Air expansion shaft releases film, and precisionizes film release, and also makes the loading and unloading of film roll more convenient.

7. The combination of air expansion shaft and braking device can adjust film release tension and speed.

8. Film cutter cuts film width to make it meet paper size. The cut film is left on the film release spindle.

9. Film perforating wheel perforates film edge for the automatic cut of laminated paper.

10. Anti-curvature device: when going through the anti-curvature device, the laminated paper shall be leveled at once and won’t curve again after cut.

11. Pneumatic cutting system realizes automatic paper cut.

12. Vibration receiving table: cut paper is sent to vibration receiving table, and will be stacked and tidied up automatically.

|

Technical Parameters |

|||

|

Model |

Pro-TFL800 |

|

|

|

Max Paper Size |

780*1040mm |

|

|

|

Min Paper Size |

350*300mmm |

|

|

|

Paper Thickness |

125-500g/ |

|

|

|

Max Laminating Speed |

40 m/min |

|

|

|

Gross Power |

22kw |

|

|

|

Total Weight |

1500kg |

|

|

|

Overall Dimensions |

4800*1650*1700mm |

|

|

vibration receiving table conveyer belt oil circulation heating system

|

Technical Parameters: |

|||

|

Model No. |

Pro-TFL1000 |

|

|

|

Max Paper Size |

1040*780mm |

|

|

|

Min Paper Size |

350*440mmm |

|

|

|

Laminating Speed |

0-40m/min |

|

|

|

Paper Thickness |

125-500g/ |

|

|

|

Gross Power |

22kw |

|

|

|

Overall Dimensions |

4800*1850*1700mm |

|

|

|

Weight |

1600kgs |

|

|

Automatic Feeder PLC control plate pneumatic stacker

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Shanghai ProMega Trading Co., Ltd. [China (Mainland)]

Business Type:Manufacturer

City: Shanghai

Province/State: Shanghai

Country/Region: China (Mainland)